This mod is made possible by the idea from Otterscustoms . I give due when it was not my idea. But I did it and can write about it.

SO, basic idea here is that if you polish your stock bolt it will be soother and will reduce friction inside of your marker. Most markers are iodinized (bolts are not) meaning that they have been subjected to a special chemical/electrical process where thin outside layer was hardened, that same layer is also very smooth. So smooth on smooth with some O-rings and lube and you got some serious back and forward action going on.

Does it work? Yes it works, it should help your marker become more consistant and you should be able to hit lower pressures if you are going low-pressure.

How to do it? Quite simple, you need/take a dremel/rotary tool (its one of those small drill like things which spin up to 5000 rpm, mine spins only 3500 rpm but its enough). They come with attachements, the polishing attachement costs about $4 in Sears, you will find the polishing compound there as well (probably right beside it). And then you polish. Remember to take off the O-rings and clean the bolt first of any paint, oil, dirt or anything else for that matter. Put the compound on the dremel tool's polishing attachement and rub against the bolt at high rpm untill you get a mirror finish. You might need to clean the bolt after some time, view the results and go back at it again. It is not a really messy job but your hands will get dirty from the compound and polished off aluminum, dish soap cleans that right off. Remember to clean the grooves where the o-rings go, if you leave them dirty first of all the bolt mught start leaking and the o-ring might break of grind down on the compound, so clean the grooves very well. Polishing the grooves inside should help the o-rings make better seal.

Right here I used an

old Pirahna rear cocking bolt, current pirahnas use much thicker and bigger

bolts (but they all fit all pirahnas), this one despite the fact that

it is about 10 years old and made from not so high quality aluminum, is

actually lighter and causes less blowback than the PMI red and green bolts.

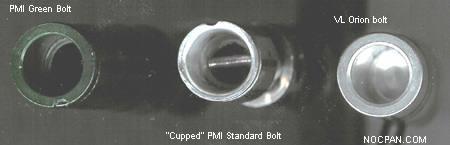

Cupping the bolt, well this is making bolt's edge that makes contact with the ball leaning inwards like a funnel. This helps in 2 things, one the bolt "grabs" and pushes the ball more gently so you avoid ball breaking because the bolt slammed into it or because the ball jumped and got crushed half way into the neck. Cupped bolt makes much better contact so when the air is released through the bolt the ball gets pushed better and more evenly. As seen on the pictures to the right, ViewLoader actually makes a somewhat cupped bolt, this can be perfected but it is a good start, whereas PMI with their standard green bolt, which appears in their electronic and semi-models now, is hardly touched, only the sharp edge is shaved. In the middle is my handi work, the older version of PMI bolt cupped so the front looks almost like a funnel.

| Special offer! If you do not have the skills (not all everyone is good with power tools and its so easy to go overboard with them), or the time to do it yourself. I will be very glad to polish and/or cup your aluminum bolt. Please e-mail me if you would like to for me to work on your bolt, I will do it for a very minimal fee and will send it back to you, but you are responsible for getting the bolt to me. I am not limited to just VL or PMI, I will work on any aluminum bolt from a stacked tube marker. |